BabyGO Autositz Babyschale »Twiner«, 2 Stück, inkl...

179,00 €

Lidl Online-Shop

ab 5,95 Versandkosten

BabyGO 3-in-1 Buggy »Halime AIR Pram«, multifunkti...

281,81 €

Lidl Online-Shop

ab 5,95 Versandkosten

Bayer Design Babypuppe »Anna First Words«, 38 cm

29,71 €

Lidl Online-Shop

ab 5,95 Versandkosten

Baby Born City RC Glam-Scooter, ferngesteuert

39,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Prosperplast Regentonne »Aquacan Baby«, Amphore, 2...

77,63 €

Lidl Online-Shop

ab 5,95 Versandkosten

BabyGO Autokindersitz »Nova 360°Rotation«, höhenve...

144,95 €

Lidl Online-Shop

ab 5,95 Versandkosten

Britax Römer Babyschale »BABY-SAFE 2 i-SIZE«, Cosm...

169,00 €

Lidl Online-Shop

ab 5,95 Versandkosten

lupilu® Baby Schlafsack, mit Bio-Baumwolle

12,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack, Außenschlafsack »Liebmi...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack, Außenschlafsack »Liebmi...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

bellybutton Baby Schlafsack, mit Baumwolle

19,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

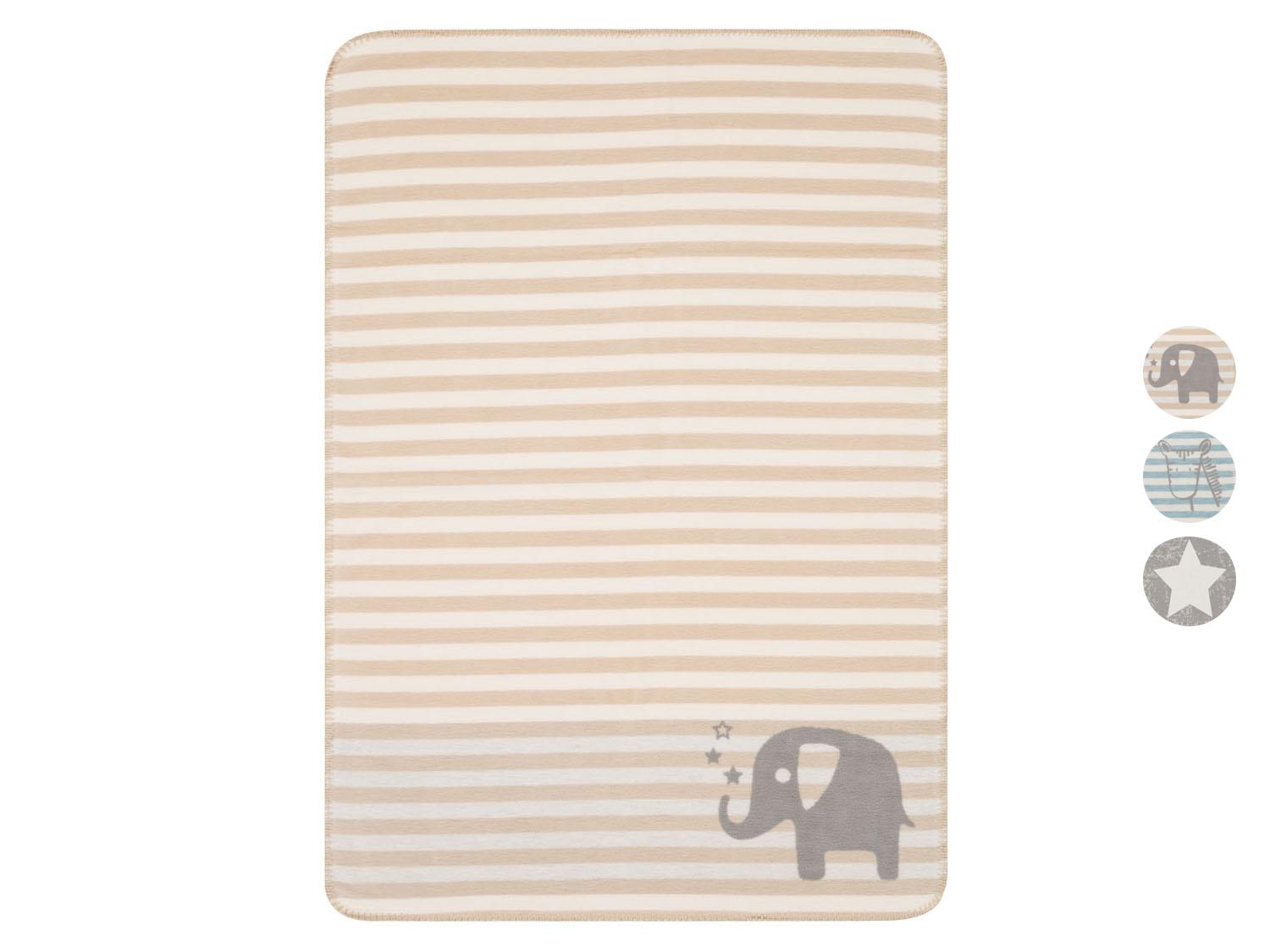

bellybutton Baby Kuscheldecke, 70 x 100 cm, aus re...

11,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Jordan 5-Piece Core Gift Set fünfteiliges Bodysuit...

35,99 €

Nike

ab 24,00 Versandkosten

Jordan nachhaltiges Set mit Jumpman-Hose für Babys...

31,99 €

Nike

ab 24,00 Versandkosten

Jordan Kleid für Babys (12–24 M) - Pink

32,99 €

Nike

ab 24,00 Versandkosten

Jordan Set aus Hoodie und Hose für Babys (12–24 M)...

34,99 €

Nike

ab 24,00 Versandkosten

Jordan Set aus Hoodie und Hose für Babys (12–24 M)...

29,99 €

Nike

ab 24,00 Versandkosten

Babyliss RS035E Heiße Lockenwickler

57,02 €

Back Market

ab 0 Versandkosten

Babyliss Curl Secret Shine C1800E Lockenstab

120,00 €

Back Market

ab 0 Versandkosten

Philips Avent Baby Monitor SCD923/26 digitales Vid...

255,00 €

Notino

ab 0 Versandkosten