BabyGO Autositz Babyschale »Twiner«, 2 Stück, inkl...

179,00 €

Lidl Online-Shop

ab 5,95 Versandkosten

BabyGO 3-in-1 Buggy »Halime AIR Pram«, multifunkti...

281,81 €

Lidl Online-Shop

ab 5,95 Versandkosten

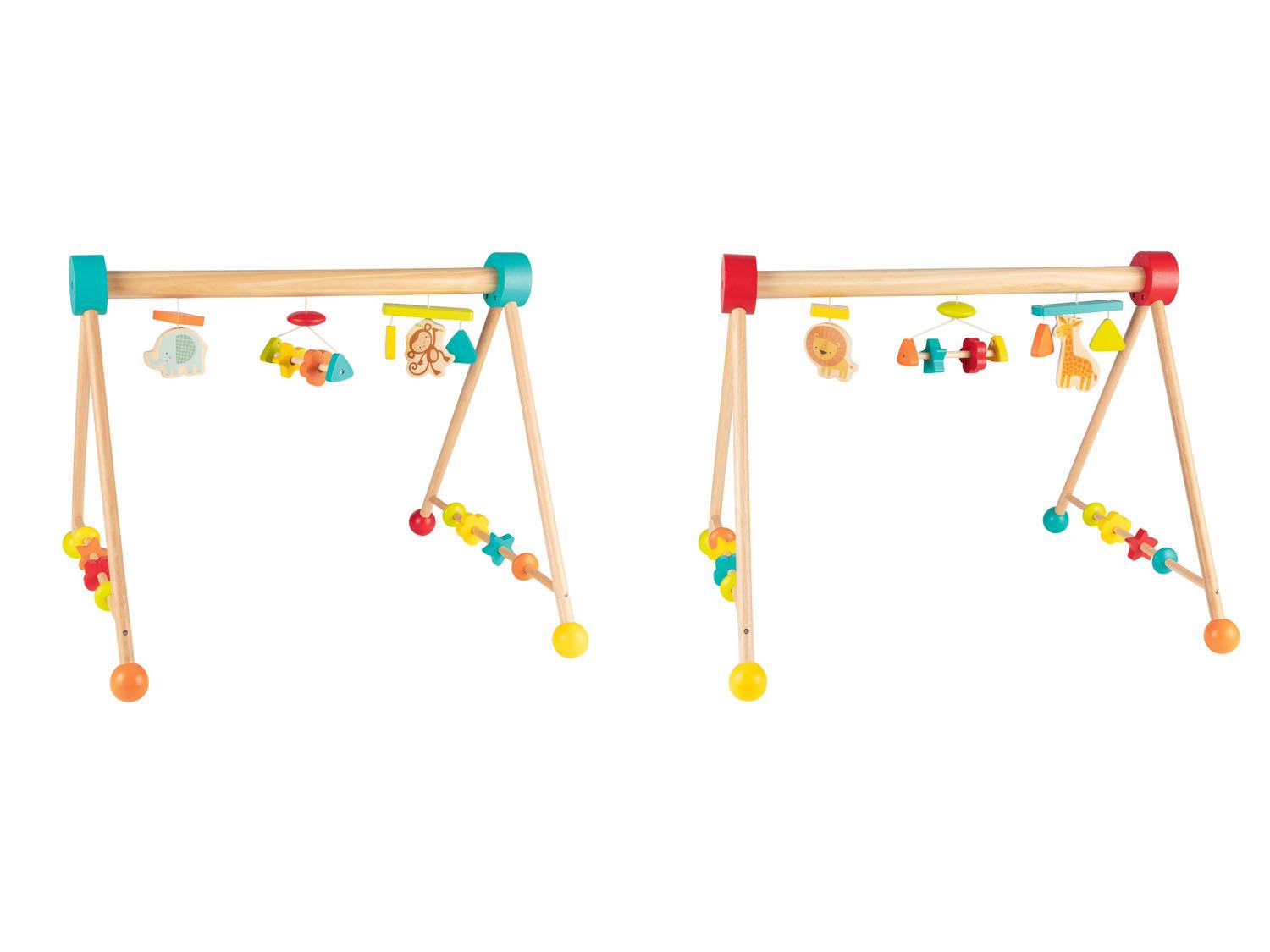

Playtive Holz Baby-Spielbogen, mit 3 Anhängern und...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Baby Born City RC Glam-Scooter, ferngesteuert

39,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Prosperplast Regentonne »Aquacan Baby«, Amphore, 2...

77,63 €

Lidl Online-Shop

ab 5,95 Versandkosten

BabyGO Autokindersitz »Nova 360°Rotation«, höhenve...

144,95 €

Lidl Online-Shop

ab 5,95 Versandkosten

lupilu® Baby Schlafsack, mit Bio-Baumwolle

12,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack, Außenschlafsack »Liebmi...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack »Liebmich«, kein Wärmest...

27,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack, Außenschlafsack »Liebmi...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Träumeland Babyschlafsack »Liebmich«, kein Wärmest...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

CYBEX SILVER Babyschale »Aton«, Rumba Red

89,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

CYBEX SILVER Babyschale »Aton«, Purple Rain

89,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

lupilu® Baby Bodies, langarm, 5 Stück, aus reiner...

14,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

lupilu® Baby Bodies, 5 Stück, kurzarm, aus reiner...

14,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Reer IP BabyCam Move, mit Bewegungs- und Geräusche...

115,95 €

Lidl Online-Shop

ab 5,95 Versandkosten

bellybutton Baby New Born Geschenkset, 4 tlg. in G...

24,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Babyliss RS035E Heiße Lockenwickler

56,78 €

Back Market

ab 0 Versandkosten

Babyliss Curl Secret Shine C1800E Lockenstab

120,00 €

Back Market

ab 0 Versandkosten

Babyliss C1201E Lockenstab

89,00 €

Back Market

ab 0 Versandkosten